Enduracomp SRL Compressor

SCROLL Technology

High performance compressed air with super quiet operation

Very low operating costs

The Enduracomp S.R.L Series lubricated scroll compressors are a simple efficient robust solution designed for the needs of the smaller industrial compressed air user.

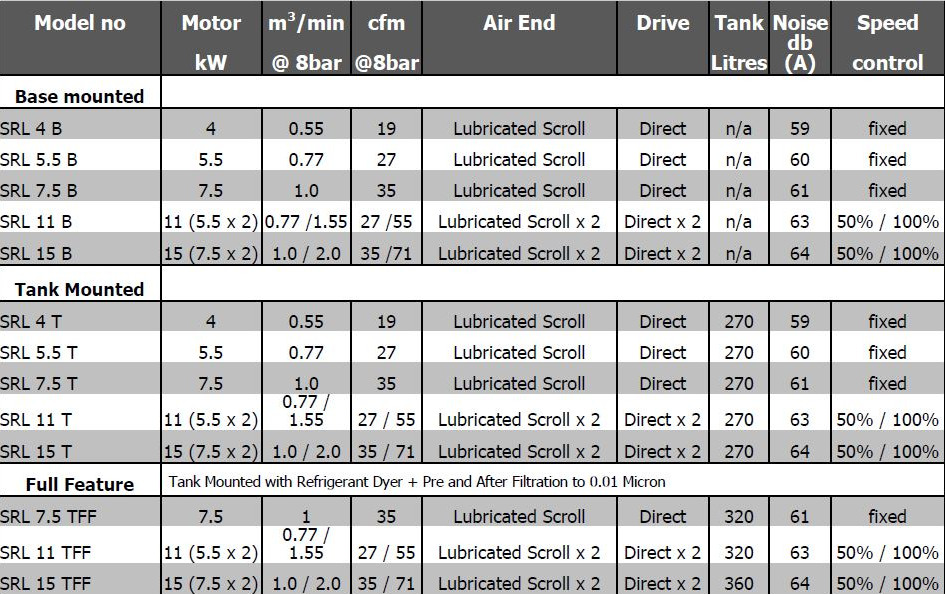

These machines range from 4kw-15kw, in three models, base, tank mounted and tank mounted ‘full feature’, the latter includes a refrigerant dryer and two filters, covering every aspect of your compressed air needs.

With one premium objective being effiency the 4-7.5 kw machines consist of a single drive train with stop start operation.

The 11-15 kw employs twin drive trains which work in conjunction with an intelligent controller.

This ensures the most economical way of utilising energy. The controller will select whether one or two units run o meet air demands, It also swaps the lead and lag system to balance out the service hours.

All compressor models eliminate expensive off load running.

Intelligent Controller – Designed to deliver efficient compressor performance

Emergency Stop Button – Safe working override device

Oil Filter – Located for serviceability

Oil / Air Separator – Spin on / off Separator for ease of service

Oil Level Display – User friendly visual oil check, making sure lubrication levels are right to avoid expensive breakdowns and downtime

Oil Drain – Simple valve allowing quick oil change

Oil / Air Cooler Outlet Vent – Positioned for effective outlet ventilation

Oil /Air Cooler With Integral Fan – Generously sized for optimum cooling of the complete system, ensuring peak performance

Intake Filter – Compressor inlet protection located again with service in mind

Stainless Steel Control / Oil System Pipework – Cheap nylon alternatives cause problems with splitting and work hardening. Stainless is much more expensive, but

lasts longer and stops unnecessary issues

Anti-Vibration Mounts – Giving smooth operation, virtually free from vibration and excessive noise

1 to 1 Direct Drive Scroll Technology With Premium Eciency I E 3 Motor – High performance compressed air with super quiet operation (59-64 db(A) and extremely low operating costs

VPM TFF SERIES

MARKET LEADING TECHNOLOGY

IE5 ULTRA PREMIUM EFFICIENCY PM MOTOR

No other screw compressor manufacturer has better efficiency

SCHNEDIER PERMANENT MAGNET VSD DRIVER

High quality German inverter system ECA approved

FULL FEATURE COMPRESSOR STATION

Complete with dryer, pre and after filtration and condensate management. Mounted on an air receiver correctly sized in line with british compressed air society “best practice program”

QUIET OPERATION

Low noise levels due to slow efficient operation.

SCF TFF SERIES

CLASSIC BELT DRIVE TECHNOLOGY

INTELLIGENT CONTROLLER

Built to save power and avoid too many motor starts

SERVICE FRIENDLY DESIGN

All items located for easy access to aid serviceability

QUIET OPERATION

Low noise levels due to slow efficient operation

FULL FEATURE COMPRESSOR STATION

Compete with dryer, pre and after filtration, condensate ready. Mounted on an air receiver, which Is correctly sized in line with british compressed air society “best practice program”

Models and Technical Specifications

Enduracomp SRL Compressors